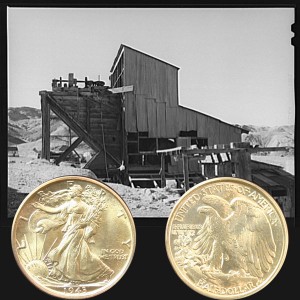

Today, the Walking Liberty Silver Half Dollar Coin tells the story of the first successful silver mill in Nevada that began on August 11, 1860.

Called the “Pioneer,” the silver mill stood at the north end of Silver City, just below Devil’s Gate.

It was a steam mill containing 24 Howland rotary stamps and 24 amalgamating pans. Work began on the mill in May, and just a few months later, it began operation in August.

Volume I of the History of Nevada published in 1913 included more details about Nevada’s first successful silver mine:

=====

In her metallurgical development Nevada presents an interesting field of study. The early attempts to work the ores of the Comstock were confined to the arrastra and amalgamation.

Almarin B. Paul, a mill man of Nevada City, California, was the first to experiment upon the treatment of the Comstock ores.

He was familiar with California mill practice and he had read extensively the literature pertaining to the treatment of silver ores.

He treated the silver sulphides with the same chemicals used in the Patio process and used the pans which were coming into use in the gold mills in California.

His experiments convinced him that the ores could be treated by this system.

He organized the Washoe Gold and Silver Mining Company, and in 1860 began the erection of a mill near the Devil’s Gate close to the present site of Silver City.

He signed contracts to work the ore from several claims in the vicinity of Gold Hill and made a treatment charge of $30 per ton.

He started his mill on August 11, 1860.

The mill was equipped with 24 stamps and the ore was crushed dry.

Knox pans were used for amalgamation. Each pan held a charge of 300 pounds, and was treated with 40 pounds of quicksilver, a pint of salt, and a few ounces of copper filings or sulphate.

The pans were heated by fires placed underneath.

Success attended the mill from the start and thus was the Washoe process introduced to the world.

Paul suggested the use of steam for heating and the Howland pan with false bottom for the circulation of steam followed.

The Wheeler, Varney, and other types of pans were soon upon the field and the process was perfected in many details, but remained the same in its essential principles.

Many mills were speedily erected. Wet crushing with the use of vats as settlers was soon introduced.

The pan developed until the standard flat bottomed pan holding a charge of 3,000 pounds of ore came into use.

By 1861 seventy-six mills were in operation.

Some experiments were made with the Freiberg amalgamating barrel, but the use of this appliance did not secure any foothold.

The treatment of comparatively high grade ore caused the tailings to run high in value and it was early recognized that re-working would in time become of importance.

The tailings were saved by running them into ponds and settling them.

In spite of this the early treatment was characterized by considerable loss of silver in the slime which was generally allowed to run to waste.

More than one of the early writers upon metallurgical methods called attention to this waste but the mine owners were making a profit and the demand for quick returns prevented any very detailed studies upon the problem of increasing the extraction and preventing waste.

Most of the early mills were placed upon the Carson River where water power could be developed.

In Washoe Valley several mills were operated for a long time.

In Virginia, in later times, several steam-driven mills were constructed.

The most notable were the Consolidated California and Virginia Mill, the Brunswick Mill on the Carson River, the Morgan Mill on the Carson River at Empire and the Mexican Mill.

In the early days Kustel and Atwood attempted the introduction of the Freiberg process, (chloridizin roasting and barrel amalgamation).

This process was adopted at the Ophir Mine, at Ball’s Mill in Washoe Valley, at the Mexican Mill in Empire, and at the Central Mill in Virginia City.

The ores of the Comstock did not require chloridizing roasting, and as a consequence the Freiberg process was soon discarded in favor of the simpler Washoe system.

The chief development in the Washoe process during the flourishing period of the Comstock was in mechanical details.

The chemistry of the process was not developed. Chemicals were used and were supposed to facilitate amalgamation.

One mill followed the practice of the other. When trouble was experienced the imagination was drawn upon for an explanation.

Witness the remedy of one millman for floured quicksilver — “the trouble arose from too great activity of the quicksilver and therefore there should be introduced into the mass opium as a sedative, in order to keep it quiet, to make it sleep and thus enable it to catch the precious metals.”

=====

The Walking Liberty Silver Half Dollar Coin shows against a derelict silver mill on the Nevada landscape, circa 1940.